G-DAF

Gener-Ox™ G-DAF Micro-Aeration

THE GENER-OX™ G-DAF - "AN INNOVATION IN DISSOLVED AIR FLOTATION TECHNOLOGY"

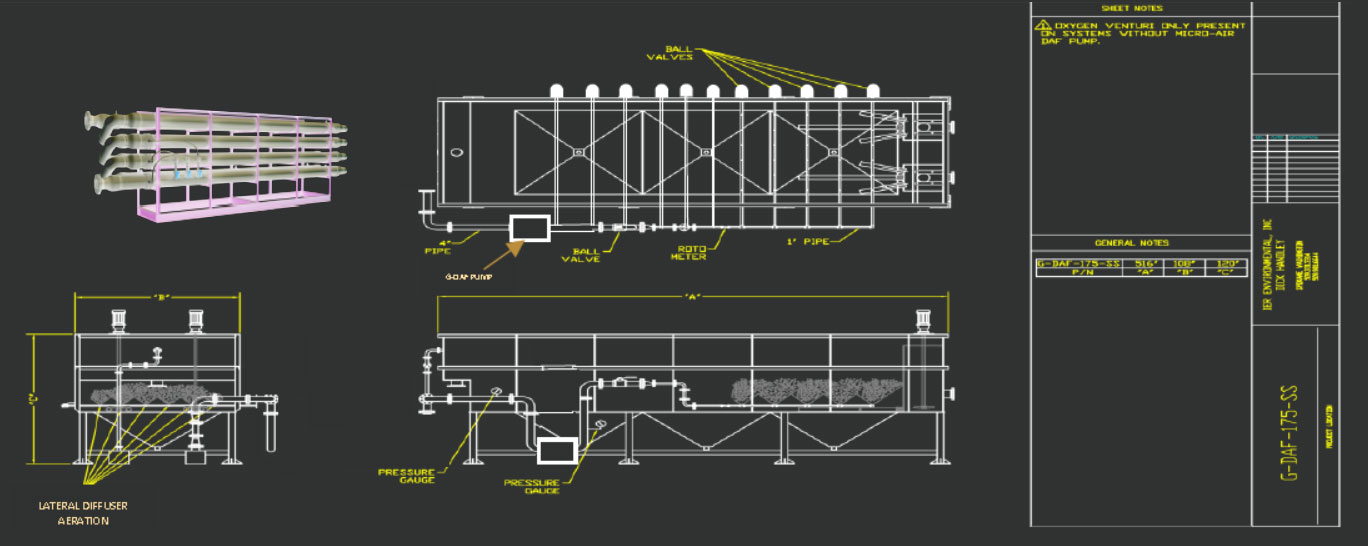

The G–DAF system is the latest technological advancement in Dissolved Air Flotation processes. The process involves the use of a patented micro-bubble aeration pump with a specially designed impeller coupled with a proprietary lateral diffuser system. This innovation provides complete micro-aeration throughout the G-DAF clarification zone.

• The system reduces energy costs while maximizing removal efficiency in total suspended solids, FOG and BOD while minimizing chemical treatment requirements.

• The Chemical usage reduction is due to the huge increase in surface area by the 10-15 micron aeration bubble cloud.

• The G-DAF system also requires a minimal re-cycle of clean process effluent (typically <15 %) as compared to most competitive DAF's of 30+% recycle.

• Since the G-DAF aeration also utilizes a patented low HP aeration pump rather than a high energy air compressor, energy requirements are reduced versus conventional DAF systems resulting in lower life cycle costs.

ADVANCED OXIDATION TECHNOLOGIES

• Gener-Ox G-DAF Air Flotation with maximized dry float solids

• Advanced Oxidation Chemistries With Ozone Gas - H202

• Soluble BOD Removal

• MBBR for BOD & TKN Removal

• Low-cost & low-energy Dissolved Air Flotation equipment

• Process water recycle/reuse Technologies

• Advanced Oxidation Chemistries With Ozone Gas - H202

• Soluble BOD Removal

• MBBR for BOD & TKN Removal

• Low-cost & low-energy Dissolved Air Flotation equipment

• Process water recycle/reuse Technologies

THE PROCESS FUNCTIONALITY OF DISSOLVED AIR FLOTATION

Dissolved Air Floatation (DAF) is a process that's intended for the removal of suspended solids from an aqueous suspension. The term "flotation" indicates substances that are floated at or near the surface of a liquid. Dissolved Air Floatation provides the needed energy to effectively float and remove suspended solids, TSS, Free Oils and Greases and other nutrients such as BOD & TKN.

• This is accomplished by the creation of extremely fine micro-aeration bubbles which become attached to the suspended nutrients and transported to the float layer for removal.

• This attachment of the micro-bubbles to the particle "reduces" the density of the suspended particle resulting in increased buoyancy, thus positively affecting floatation. Chemical coagulants & flocculant chemistries are often used to increase the effectiveness of the dissolved air floatation process via a particle charge modification or neutralization.

• The most reliable and positive method of producing very low micron sized bubbles is by dissolving air into water under pressure as with the Gener-Ox™ G-DAF pump and then to reduce the pressure of the solution as it's returned to the flotation vessel.

• As the pressure is reduced, the air volatilizes from solution in the form of <15 micron-sized aeration bubbles.

G-DAF Micro-Aeration results in Extraordinarily High Dry Float Solids

• Floatation solids from most dissolved air flotation systems historically peak in the range of approx 8% dry solids.

• The G-DAF system routinely produces dry solids in excess of 12%.

• This increase results from the massive volume of micro-air exiting from the diffuser laterals below the clarification zone.

• This high volume of micro-air has to travel through the float solids layer to exit the system thereby producing the elevated dry solids.

• This increase in dryness often eliminates the need and expense of additional dewatering equipment.

Innovative G-DAF Aeration Pump

• Through the innovation of the patented G-DAF pump impeller design, the aeration pump is able to create a sub-atmospheric pressure region in the seal chamber, thereby forming compressed micro-bubbles which are then dissolved into the pump discharge.

• This process eliminates the need for an air saturation tank or air compressor which are often required in many DAF systems.

• The G-DAF Pump innovation definitely enhances the performance of IER's newly constructed G-DAF systems and also enables significant removal efficiency in DAF systems after retrofit with the Gener-Ox™ G-DAF Pump.

G-DAF Aeration Diffuser laterals – Full Aeration Coverage throughout the DAF clarifier zone

• The fine bubble cloud results in extremely high dry float solids as well as enhanced removal of colloidal solids and FOG.

• The G-DAF micro bubble aeration cloud is illustrated below in a video demonstration.

CASE STUDY

A fish processing plant on the central coast of Oregon operates a conventional DAF system using compressed air introduced through a recycle stream for supply of influent aeration. This DAF unit operates at a flow rate of approximately 300 GPM. The Corporate Environmental Manager inquired as to assistance regarding a potential aeration retrofit for the purpose of allowing higher hydraulic throughput while also generating improved nutrient removal rates for TSS, FOG & BOD reduction efficiency. A recommendation was made to install a Gener-Ox™ G-DAF aeration pump along with a lateral diffuser system throughout the clarification zone of their DAF unit. The retrofit included an 80 GPM G-DAF micro aeration pump combined with the horizonal lateral diffuser design that's utilized in IER's G-DAF design. The plants basis of tracking performance was by turbidity analysis via a Hach NTU instrumentation measurement. The starting baseline point for the test period was a turbidity average level of 154 NTU's.

Following are direct comments from the Plant Engineer regarding the G-DAF pump testing.

The Gener-Ox™ G-DAF pump was initially turned off with NTU's then averaging 154. After 15 minutes of run time with the Gener-Ox™ G-DAF pump off line, the NTU average had climbed to 267 NTU's. The G-DAF pump was then turned back on and after 15 minutes the NTU average had decreased to 146 NTU's.

Therefore in summary, the test process resulted in the G-DAF pump decreasing the turbidity by 121 NTU's. This reduction correlates to a TSS reduction of 120 Mg/l and a BOD reduction of 500 Mg/l. This correlation is based on previous 3rd party laboratory correlation analysis which had been performed by the processor.

← Back to Liquid Solids